News Story

UMD Leads Development of Safer Water-in-Salt Electrolyte Lithium Battery

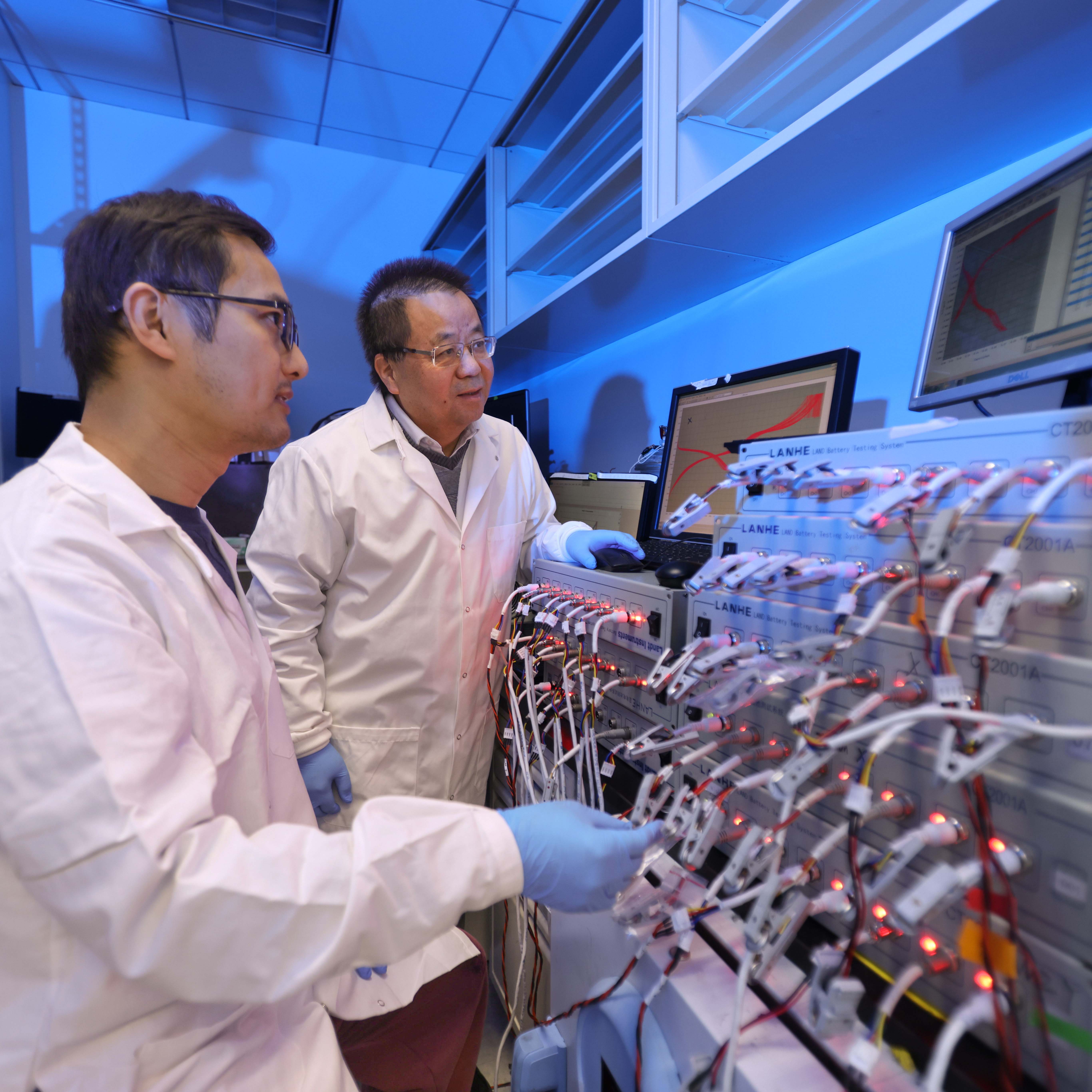

University of Maryland (UMD) and US Army Research Lab (ARL) researchers, led by Professor Chunsheng Wang, are spearheading a public-private sector collaboration to further develop a lithium battery that would be safer to operate and less costly to dispose of than those currently available on the market. Their breakthrough involves using a high concentration of salt in aqueous lithium batteries to boost their energy density and viability. The UMD-ARL team won the Invention of Year of UMD in 2016.

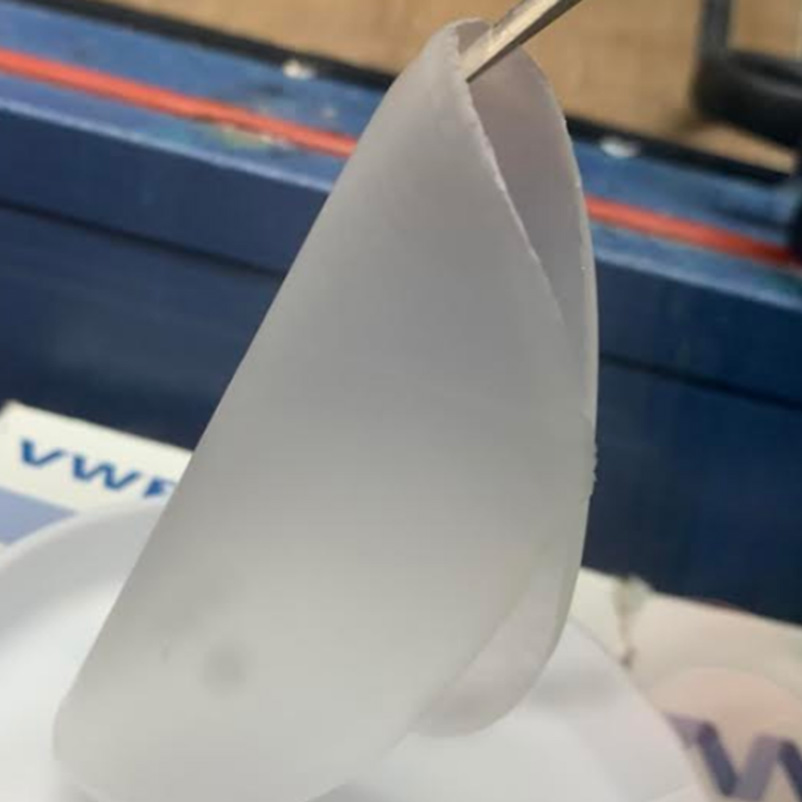

A key attribute of such a high energy density aqueous battery is it is not flammable. Historically, though, lithium batteries with aqueous electrolytes have been limited in their energy density. Prof. Wang and Dr. Liumin Suo at UMD were collaborating with Drs. Kang Xu, Oleg Borodin and Arthur Von Cresce at ARL. They

achieved a higher energy density by forming a solid-electrolyte interphase (SEI) with a salt with a high solubility in water, specifically lithium bis(trifluoromethane sulfonyl)imide (LiTFSI). The establishment of a SEI during initial charging expands the electrochemical stability window of aqueous electrolytes to ~3.0 V.

This water-in-salt electrolyte lithium battery recently achieved an energy density of 200 Wh/kg, noted Dr. Wang at UUM, who added the DOE had sought 150 Wh/kg, or double that of a traditional aqueous Li-ion battery. "The researchers in the field and program managers alike are very excited," Dr. Xu at ARL said, adding the next target is 300 Wh/kg.

The water-in-salt electrolyte idea was derived from the high concentration salt use in organic electrolytes for traditional lithium batteries, Wang related. Lithium batteries with organic electrolytes already use a "very high concentration salt to stabilize the anode and the cathode, but nobody tried this idea in the water. We are the first to borrow this idea from organic electrolytes but apply it in the hydrous lithium battery."

Their initial findings, published in Science Magazine last November, won the backing of the Department of Energy for a second phase of research with matching from UMD and private companies. The project began as research collaboration between UMD and the Electrochemistry Branch, Sensor and Electron Devices Directorate of the Power and Energy Division of the U.S. Army Research Laboratory in nearby Adelphi, Maryland. The second phase is anticipated to start soon with a total of $4 million in funding for three years. The research teams are providing $1 million in matching funds and requested $3 million from DOE. This second phase will comprise teams from UMD and the Army Research Lab as well as Saft and Liox from the private sector.

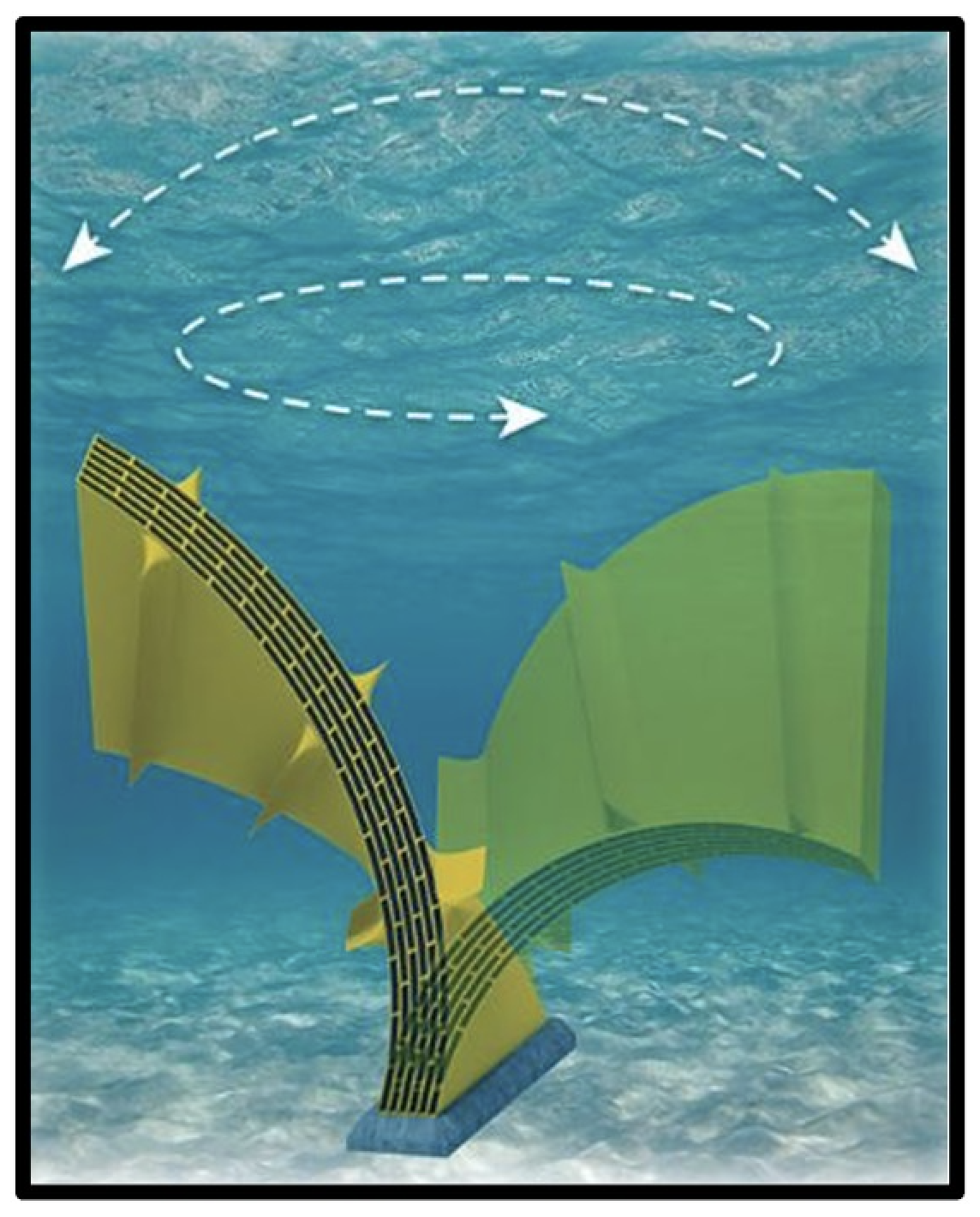

One of the main objectives of the second phase of the project is to lower the cost of the electrolytes with alternative salts or mixed salts. The goals are also to enhance the energy density and cycle life of the batteries, and bring out a commercial demonstration cell. Liox and Saft are to cooperate on commercializing high energy density aqueous batteries for use in electric vehicles, according to the proposal for phase 2.

One goal is to deliver a 500 Wh battery storage unit to DOE for evaluation. Another application in mind is an aqueous Li-ion batteries to be delivered to the Army's Tank Automotive Research Development and Engineering Center (TARDEC).

A provisional patent for Aqueous and Aqueous/Non-Aqueous Hybrid Electrolytes with Wide Electrochemical Stability Windows was filed with the U.S. Patent Office in 2015.

Published August 9, 2016