News Story

ChBE Researchers Develop Clean, Efficient Method of Natural Gas Conversion

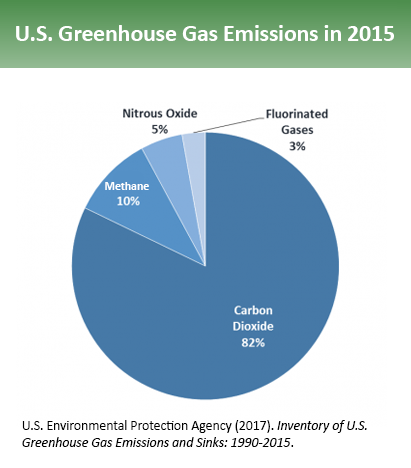

One of the world’s most heavily utilized energy resources is natural gas, accounting for roughly 20% of the world’s energy supply. Natural gas, which is generally odorless and devoid of color, is composed of multiple compounds, primarily methane. When directly released into the atmosphere – as opposed to being burnt – during the fracking process (i.e. shale gas), or the transport of coal, for example, methane becomes a dangerous, greenhouse gas, trapping heat in the Earth’s atmosphere and contributing to global warming. If methane could be harnessed into hydrocarbon, or even liquid, form it would be easier to transport and less likely to increase pollution.

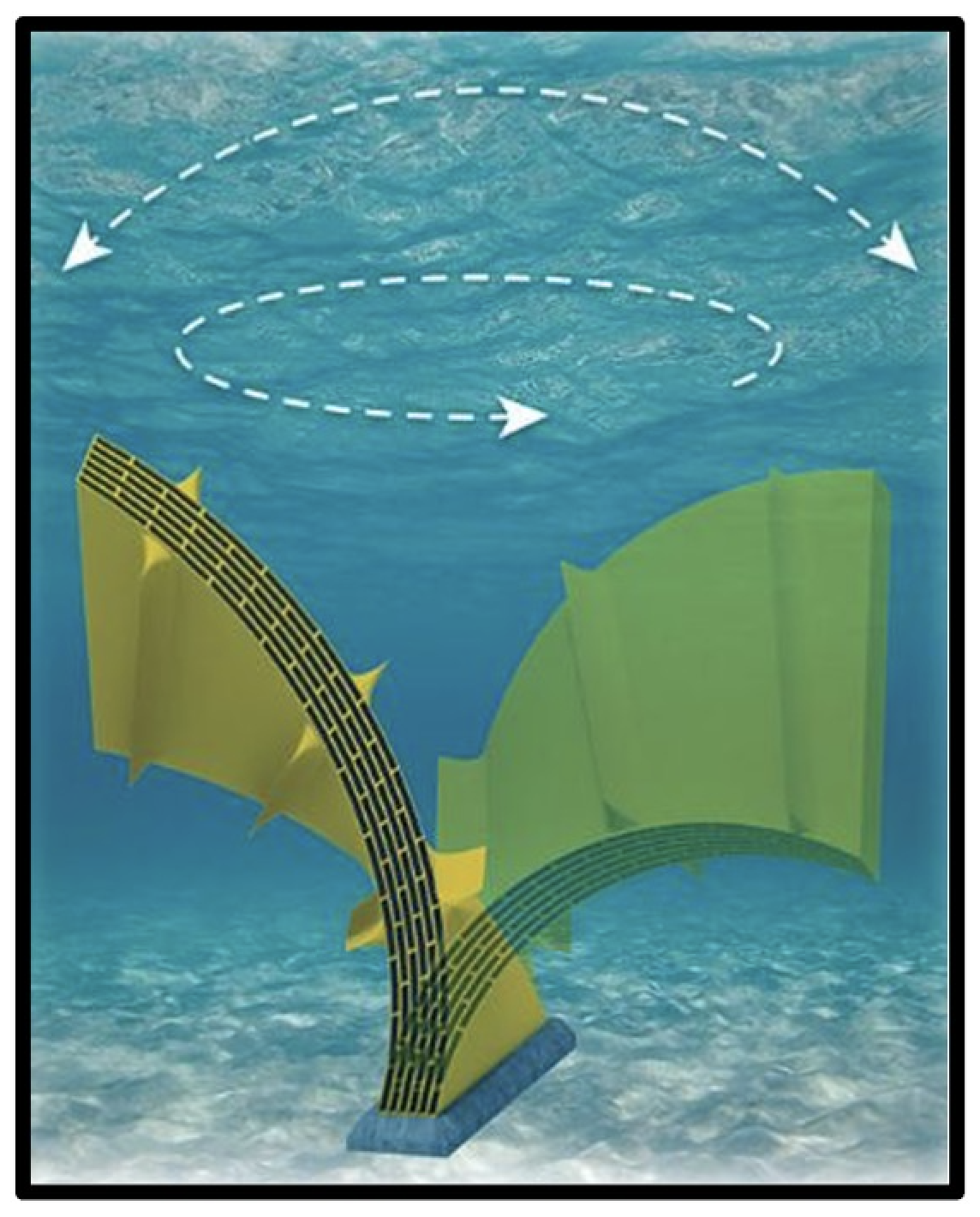

To that end, researchers in the Department of Chemical and Biomolecular Engineering (ChBE) at UMD are developing a method of converting methane to other valued-added materials, such as C2 hydrocarbons (e.g., acetylene, ethylene, ethane) and higher hydrocarbons such as aromatics (e.g., benzene and naphthalene). Current converters use a catalytic oxidation process to make these hydrocarbon materials, but generate harmful CO and CO2 chemicals. This ChBE research group, led by Drs. Dongxia Liu and Eric Wachsman, have created a single-step converter: a hydrogen-permeable tubular membrane reactor via non-oxidative methane conversion to harness these chemicals from methane.

“The route for this one step process is limited by the thermodynamics of the reaction, which can be circumvented by using a membrane reactor,” said Mann Sakbodin, a graduate student in the Department of Chemical and Biomolecular Engineering and first author on the research paper. “By combining a membrane reactor and a catalyst, we can improve the methane utilization and maximize the product yields.”

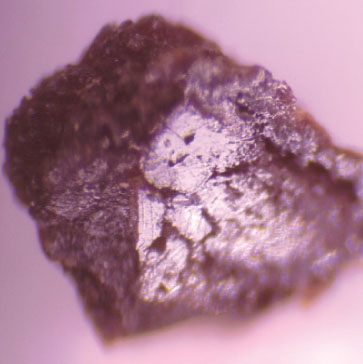

The reactor, which is the size of a drinking straw, is patented, metal oxide ceramic material, thermally stable, hydrogen-permeable and very strong. This mechanism has the ability to do both chemical separation and reaction simultaneously – it removes the hydrogen component of the products, and pushes it through the reactor, driving methane into more value-added hydrocarbon materials.

The group is currently in the process of extending the capabilities of the membrane reactor system. Specifically, they’re looking at using different ‘sweep gases’ (e.g. helium, dual production on both feed and sweep sides), and optimizing the system to maximize the product capability. The hope is to commercialize the product - sell it to oil companies, for example - in the near future.

This research entitled, “Hydrogen-Permeable Tubular Membrane Reactor: Promoting Conversion and Product Selectivity for Non-Oxidative Activation of Methane over an FeÓSiO2,” was published in Angewandte Chemie in November, 2016 (DOI: 10.1002/anie.201609991).

Published July 6, 2017