News Story

3D-Printed Evaporator is Sustainable Approach to Water Shortage

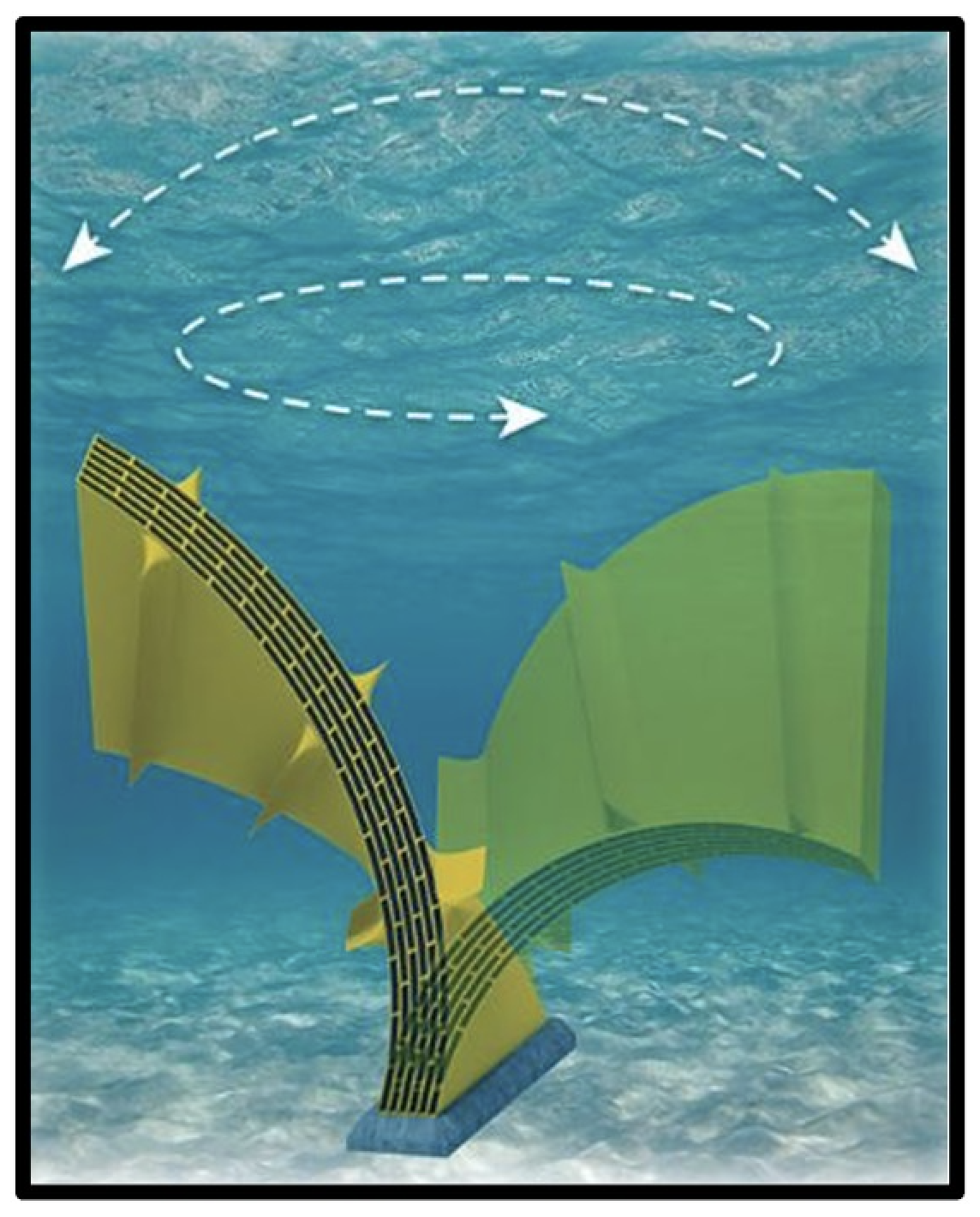

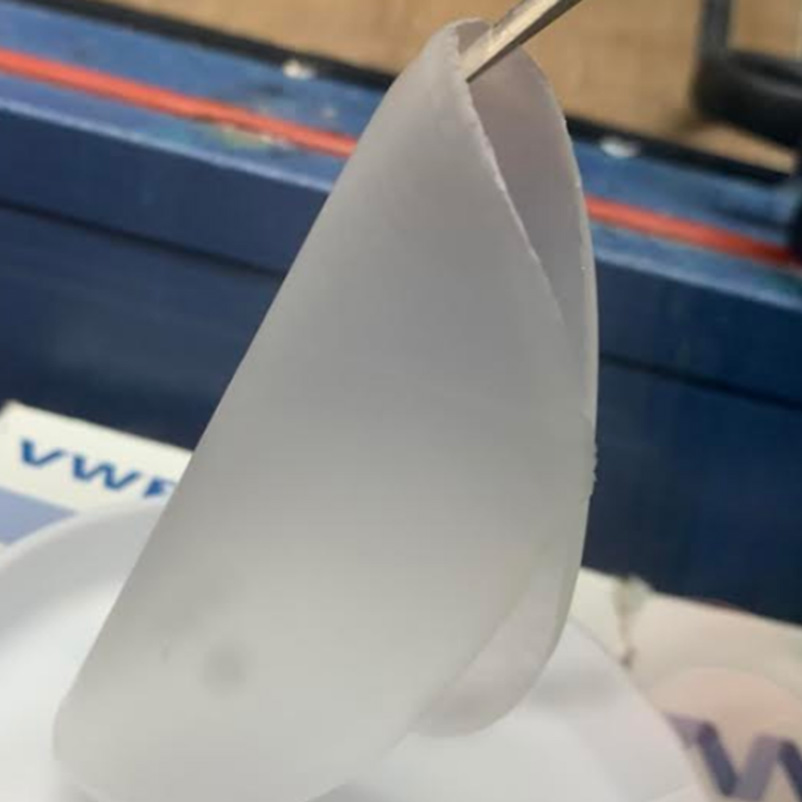

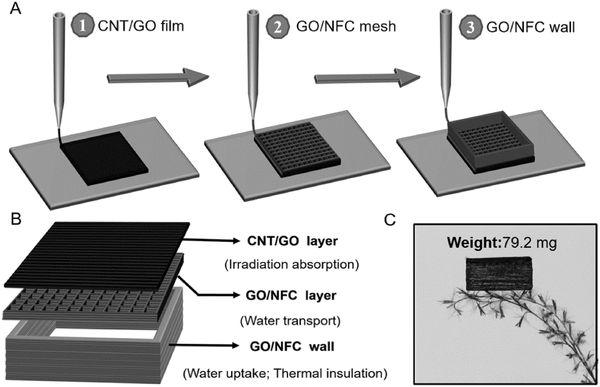

Schematic illustratio of 3D printing process and sample structure.

Recent and severe drought has affected more than a third of the United States over the past 5 plus years. This limited water availability constrains the operation of some power plants and other energy production activities. Furthermore, the recent growth in domestic unconventional oil and gas development has added a level of complexity to the relationship between energy and water resources.

However, Liangbing Hu, and his colleagues at the University of Maryland Energy Research Center (UMERC) in College Park recently built a device using a 3D-printed material made of carbon nanotubes and graphene oxide, which absorbs 97% of incoming sunlight and rapidly warms up. Using solar energy to generate steam they have produced a clean and sustainable method to alleviate water shortages.

Currently most existing solar evaporation strategies involve heating the bulk water and are extremely inefficient in energy harvesting. The 3D-printed device uses 85.6% of the absorbed energy to generate steam, which is one of the highest efficiencies achieved by evaporators. The approach could help to ease shortages in areas where water has to be sterilized or desalinated, the authors say. The evaporator has a low thermal conductivity that enables heat localization and reduces thermal dissipation to the bulk water.

This research entitled, “3D-Printed, All-in-One Evaporator for High-Efficiency Soalr Steam Generation under 1 Sun Illumination,” was published in Advanced Materials on May 15, 2017 (DOI: 10.1002/adma.201700981).

Published June 22, 2017